Sustainable innovation

Innovative low-carbon packaging solutions for the food industry

SIG Terra Alu-free + Full barrier offers up to

-25

%

lower carbon footprint than our standard aseptic cartons1

Innovation towards higher recyclability of products or less resource-intensive products will positively impact SIG’s entire value chain.

SIG’s packs are among the most sustainable packaging solutions in each relevant market segment – and we are innovating to reduce their environmental impact even further.

Independent life-cycle assessments show our carton, bag-in-box and spouted pouch solutions offer significant reductions in environmental impacts compared with other types of packaging, such as disposable glass, plastic tubs and bottles, or cans.2

Our packs’ strong environmental credentials are an important differentiator as market demand for more sustainable packaging continues to grow. Choosing our solutions helps customers respond to rising consumer expectations, comply with increasingly stringent regulations, and achieve their sustainability ambitions.

We strive to make our packs even more sustainable through innovation. Across our portfolio, we are innovating to design more recycle-ready3 packs that optimize material use and reduce carbon emissions further by removing or reducing carbon-intensive materials and by replacing virgin fossil-based polymers with renewable or recycled alternatives.4 We are also creating new solutions to further reduce the resources needed to fill our packs in customers’ factories.

We have already achieved a host of industry firsts (see Our sustainable innovation journey). Our SIG Terra portfolio showcases our most sustainable innovations – including aseptic cartons with no aluminum layer, polymers linked to forest-based and recycled materials,4 and recycle-ready bag-in-box and spouted pouch solutions.

Our sustainable innovation journey so far

Our starting point

Standard SIG aseptic carton and filling machine

- Beverage cartons made of, on average, 75% FSC™ certified renewable paperboard,5 21% polymers, and an ultra-thin layer of aluminum foil.

- 28–70% lower carbon footprint than alternative packaging, such as plastic and glass bottles, and aluminum cans.6

- Industry-leading waste rate (<0.5%) through highly efficient filling process.

2010

SIG Terra Alu-free7

- World’s first packaging material for aseptic cartons with no aluminum layer.

- 82% renewable paperboard.

- Up to 23% less carbon than standard SIG packaging material for aseptic cartons.6

- For use with dairy products.

2013

SIG Dome8

- Looks and pours like a bottle.

- Environmental benefits of a carton.

2016

RS structure

- Reduces plastic use while improving the robustness of our aseptic cartons during processing and distribution.

2017

SIG Terra Alu-free + Forest-based polymers9

- World’s first aseptic carton with all main materials linked to forest-based renewable resources.10

- No aluminum foil layer.

- Up to 63% less carbon than standard SIG packaging material for aseptic cartons.6

- For use with dairy products.

2018

SIG Terra Forest-based polymers10

- Polymers linked to renewable resources.11

- Ultra-thin aluminum foil layer to protect oxygen-sensitive products, such as orange juice.

- Up to 41% less carbon than standard SIG packaging material for aseptic cartons.6

2019

Paper straw solution

- World’s first paper straw for use with aseptic carton packs.

- Straight, U-shaped, and telescopic options.

- FSC™-Mix certified.

2019

ASI-labeled packs

- World’s first aseptic carton packaging materials with ASI aluminum foil.

- First product with ASI aluminum foil and ASI on product label.

- The only cartons that can carry the ASI Responsible Aluminium Sourcing logo.

2020

SIG Terra Circular polymers12

- World’s first aseptic carton solution offered with post- consumer recycled content.

- Polymers linked to recycled plastics.2

2021

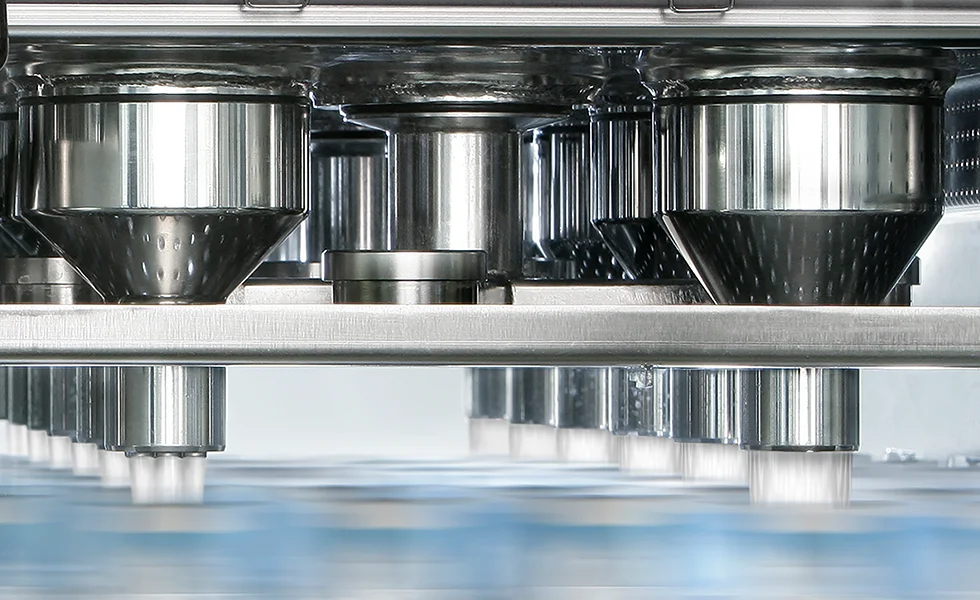

SIG Neo

- Next-generation filling machine for family-size aseptic carton packs.

- 25% less carbon by design for the filling and packaging per pack.13

- 30% less consumables by design (hydrogen peroxide, compressed air, and water).13

2022

SIG Terra Alu-free + Full barrier14

- World’s first full barrier solution for aseptic cartons with no aluminum foil layer.

- For use with both liquid dairy and oxygen-sensitive products, such as fruit juices, nectars, flavored milk, or plant-based beverages.

2022

Bag-in-box and spouted pouch solutions join our portfolio

- High product-to-packaging ratio.

- Less carbon than alternatives, such as plastic and glass bottles, tubs, and jars.1

- Recycle-ready mono-material spouted pouch.

- First APR-recognized recycle-ready bag-in-box.15

- World’s first bag-in-box linked to recycled content.4

2023

SIG Dome Mini

- Portion size.

- Looks and pours like a bottle.

- Environmental benefits of a carton.

2023

SIG Terra Alu-free + Full barrier commercially available

- World’s first full barrier solution for aseptic cartons with no aluminum foil layer launched commercially in China.

- Up to 25% less carbon than standard SIG packaging material for aseptic cartons.1

2024

SIG Terra Alu-free + Full barrier + Forest-based polymers commercially available

- World’s first full barrier solution for aseptic cartons with no aluminum foil layer and linked to forest-based polymers available globally.

Our commitments

Innovation in products and services can address potential negative impacts from our business. Hence we are committed to investing in research and development to help customers and consumers make more sustainable packaging choices.

Our approach

Sustainability criteria are core value drivers in all our product development, alongside other critical factors such as safety and affordability. Our Innovation Board regularly reviews our entire innovation pipeline in the light of evolving sustainability considerations, such as forthcoming regulations and customer needs.

We have established clear internal guidelines on sustainable packaging design for our cartons, and separately for our bag-in-box and spouted pouch solutions, with accompanying training for relevant teams. These guidelines include detailed market-level criteria on design for recycling.

Our marketing and sales teams are trained and incentivized to increase customer uptake of our most sustainable solutions, which in turn helps us amplify our net positive impact across our sustainability action areas.

Taking a life-cycle approach

We evaluate the environmental impacts of our packaging innovations through robust life-cycle assessments (LCAs) carried out by credible independent not-for-profit institutes, using the ISO 14040 and ISO 14044 international standards and critically reviewed by an independent expert panel.

LCAs consistently confirm that our packs offer significant reductions in environmental impacts compared with alternative types of packaging and our SIG Terra solutions lower the impact of our aseptic cartons even further. See charts below.

Life-cycle carbon footprint: How our aseptic cartons compare16

Liquid dairy

kg CO2 equivalent per packaging required for 1,000 liters UHT milk

Non-carbonated soft drinks

kg CO2 equivalent per packaging required for 1,000 liters non-carbonated soft drinks

Food

kg CO2 equivalent per packaging required for 1,000 liters food

Life-cycle carbon footprint: additional savings with SIG Terra solutions for aseptic cartons

kg CO2 equivalent per packaging required for 1,000 liters of milk or juice in 1 liter SIG SlimlineBloc pack format (with SIG SwiftCap)1

Optimizing use of materials

We already optimize material use in our existing solutions through:

- the exceptionally high product-to-package ratio of bag-in-box and spouted pouches

- our innovative RS structure that reduces the amount of polymers needed to make our aseptic cartons

Our standard procedures mandate that new packaging designs must demonstrate optimized resource use compared with previous models, while continuing to deliver the quality and functionality that customers and consumers demand.

Removing aluminum foil

Aluminum foil makes up only around 4% of an aseptic carton, but a much higher proportion of its life-cycle carbon footprint. We have led the industry with the first solutions for aseptic cartons that remove the need for the aluminum foil barrier layer:

- SIG Terra Alu-free for use with oxygen-insensitive products, such as white UHT milk

- SIG Terra Alu-free + Full barrier, which offers the full barrier properties required to preserve oxygen-sensitive products, such as juices

We are working to achieve cost parity of our SIG Terra Alu-free packaging materials with our standard materials for aseptic cartons to support increased uptake.

Increasing renewable or recycled content

A priority for our sustainable innovation is to find ways to introduce renewable or recycled alternatives to virgin fossil-based polymers. We are doing this by linking polymers to renewable or recycled content using a mass balance system.17 See Resource+

Designing for recycling

All our cartons are already designed to be fully recyclable18 and we are innovating to make more of our bag-in-box and spouted pouch solutions recycle-ready. See Resource+

Reducing resource use in filling

Our highly efficient filling machines for aseptic cartons offer the lowest waste rate in the beverage carton industry, with just 0.5% or less of our packs wasted during filling. With continued innovation we aim to further improve the environmental footprint of our filling machines, in turn aiming to mitigate climate-related risks.

We aim to reduce the amount of resources needed to run the machines at our customers’ factories by designing every new machine to use resources even more efficiently. This includes energy for heating and sealing the packs, as well as compressed air, hydrogen peroxide, and water used in cleaning, sterilization and packaging processes.

Reducing life-cycle impact

Through transparent and comprehensive studies on the environmental performance of our solutions, we enable customers and consumers to make more informed choices.

- We completed full LCAs of our bag-in-box for wine and our spouted pouch for fruit purees in Europe (USA ongoing), including critical review. The 3L Bag-in-Box (Durashield 34AL with CellarTap) performs better than standard and lightweight glass bottles for wine in all impact and inventory categories, cutting the carbon footprint by 77% to 81%.

- For our spouted pouches (RecShield B and ClearShield with Amerigo spout) the comparative life-cycle assessment for fruit-based puree/kids food revealed better results for Europe than glass jars and plastic tubs in all impact and inventory categories, cutting the carbon footprint by 79% vs. glass jars and by up to 50% vs. plastic tubs.

Designing for circularity

- We are working with our bag-in-box wine customers in North America on shelf-life testing of SIG Terra RecShield BD, a recycle-ready laminate which features durability and a strong oxygen barrier, and SIG Terra Flexitech Circular Polymers, a film made with polymers linked to post-consumer recycled plastics.

- We are in discussions with major global brands to offer our aseptic cartons with SIG Terra Circular polymers linked to post-consumer recycled plastics19 to help them transition to circular packaging and comply with growing regulations related to recycled plastic content.

- Our recycle-ready 10 and 20 liter SIG Terra RecShield 102B bag-in-box for post-mix syrup has been launched in Indonesia. This bag, including its fitment, is made from 97% polyethylene to support recycling and cuts greenhouse gas emissions by 17%.20

- In North America, our SIG Terra Versi Connect 2750 bag-in-box for post-mix syrup featuring SIG Terra RecShield D has passed third-party testing and was formally recognized by the Association of Plastic Recyclers (APR) as meeting the highest criteria for recyclability according to the APR Design® Guide.

- Our recycle-ready SIG Terra RecShield PP pouches, developed in partnership with a major EU customer, have passed shelf-life testing after pasteurization and are now starting the roll-out.

- In partnership with a major European brand, we launched a tethered reclosable cap for beverage spouted pouches, that in addition to complying with EU legislation, is lightweight, saving 14% material versus previous designs.

We developed tethered cap solutions, which ensure the cap is kept together with the pack for recycling, for all SIG pack formats for beverage packaging sold in Europe, ahead of EU regulatory requirements that came into force in July 2024.

Assessing effectiveness

We perform Internal audits and regular reviews of progress by our Responsibility Steering Group and our Group Executive Board.

Responsibility for managing sustainable innovation:

- Global Technology.

- Global Research & Development.

- Global Engineering & Application teams.

Support from Global Marketing and the Chief Technology Officer

Our targets and performance

Our innovation targets are aligned with those of our Resource+ action area.

Targets, progress and performance

Target |

|

Progress tracker |

|

2024 performance |

||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Material topic: Innovation in products and services |

||||||||||||||||||

Launch a full barrier carton with all main materials linked to renewable |

|

|

2024 performance is reported under Resource+. |

|||||||||||||||

Develop a full barrier aseptic carton with at least 85% paper2 content (excluding closure) by 2025 – and at least 90% paper content (including closure) by 2030 |

|

|

2024 performance is reported under Resource+. |

|||||||||||||||

Offer a recycle-ready3 bag-in-box and spouted pouch solution in all our relevant market segments by 2025 |

|

|

2024 performance is reported under Resource+. |

|||||||||||||||

Reduce energy use by 20%, hydrogen peroxide use by 35%, and water use by 25% per hour of runtime in our next-generation filling machine for mid-size format aseptic carton packs4 by 2025 |

|

|

The commercial ramp up phase of the SIG NEO XLR filling platform has been postponed to early 2025 as several operational improvements have been identified and implemented during the test phase in 2024. |

|||||||||||||||

Reduce use of consumables by 25% for the next-generation filling machine for small- format aseptic carton packs5 by 2025 |

|

|

Pre-development projects to sharpen the concept for our next-generation small-size filling machine were initiated in 2024. These will enable us to achieve our ambitious reduction target. |

|||||||||||||||

|

||||||||||||||||||

Progress in 2024

Growing uptake of our most sustainable innovations

- Across our packaging portfolio, we have now sold enough packs with SIG Terra solutions to fill around 6 billion liters of food. In 2024 alone, approximately 1.7 billion liters of food were packed in packs with SIG Terra packaging materials. SIG Terra solutions accounted for 5.5% of the food packed in SIG packaging globally in 2024.

- Sales of our SIG Terra packaging materials for aseptic cartons increased by 15.1% this year, with further expansion in Europe, as well as a SIG Terra Alu-free Full barrier sales ramp up in China. SIG Terra solutions in aseptic cartons accounted for 9.3% of the food packed in SIG aseptic cartons in Europe – where uptake has remained strong – and 4.1% worldwide. The number of packs sold in 2024 labelled with ASI logo has surged by more than 60% vs. 2023 thanks to SIG’s dedication to promoting responsible sourcing practices.

- All our EU customers requiring tethered caps to comply with EU regulations were able to switch to our linked closures in time to meet the July 2024 deadline.

- We have now sold over 1.3 billion small-format on-the-go packs with our paper straw solutions, which offer a renewable alternative to plastic straws and now focus on supporting customers direct sourcing choices that comply with growing regulations on single-use plastics.

2024 success story: Bag-in-box in Australia-New Zealand

- Three water companies in the Australia-New Zealand region have begun the process of upgrading their bag-in-box packaging to our SIG Terra OptiTap 2300 product that features our recycle-ready RecShield film.

- Our first wine customers are preparing to switch to recycle-ready SIG Terra bag-in-box solutions. Six customers in the region are in active planning to re-launch their wines in our SIG Terra OptiTap bag-in-box solution in late 2024 and early 2025.

2024 success story: aseptic beverage carton with no aluminium layer available in Poland

- 2 dairy companies started selling milk in the Polish market packed in SIG Terra Alu-free as interest for lower carbon solutions continues to grow in further EU countries.

KPIs

Metric |

|

2020 |

|

2021 |

|

2022 |

|

2023 |

|

2024 |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Sustainable innovation |

|

|

|

|

|

|

|

|

|

|

||||||

Material topic: Innovation in products & services |

|

|

|

|

|

|

|

|

|

|

||||||

Food packed with SIG Terra1 packaging materials (million liters) |

|

457.22 |

|

540.92 |

|

613.52 |

|

1,544.2 |

|

1,683.6 |

||||||

Food packed in SIG Terra1 packaging materials |

|

3.12 |

|

3.52 |

|

3.42 |

|

5.3 |

|

5.5 |

||||||

SIG aseptic carton packs sold labeled with ASI logo (million packs) |

|

80.0 |

|

577.0 |

|

1,383.7 |

|

2,801.0 |

|

4,564.5 |

||||||

|

||||||||||||||||

Our positive impact

Through our sustainable innovation, we contribute to the United Nations Sustainable Development Goals.

Innovation towards higher recyclability or less resource-intensive products positively impacts SIG’s entire value chain and can reduce the quantity of virgin plastic and aluminum used. While investment in innovation can have a negative financial impact on our business in the short term, it creates longer-term value. It mitigates negative impacts on the environment and on society, including on human rights.

1 Based on independent ISO-compliant life-cycle assessment. Data has been critically reviewed and the full report is published on our website.

2 For a wide range of food and beverages, based on independent critically reviewed life-cycle assessments for beverage carton, bag-in-box and spouted pouch solutions conducted in line with ISO 14040 and ISO 14044 standards.

3 In line with Design for Recycling criteria developed by APR (Association of Plastic Recyclers) and Recyclass.

4 Via an independently certified mass balance system.

5 Our cartons use paper-based liquid packaging board, referred to throughout as “paperboard”. SIG uses FSC™ Mix material that allows the mixing of FSC™ certified wood with FSC™ controlled wood and ensures that an equivalent amount of FSC™ certified wood is procured at the beginning of the value chain.

6 Based on independent ISO-compliant life-cycle assessments.

7 First launched as combibloc ECOPLUS.

8 First launched as combidome.

9 First launched as SIGNATURE 100.

10 Polymers linked to wood residues from papermaking via an independently certified mass balance system.

11 First launched as SIGNATURE FULL BARRIER.

12 First launched as SIGNATURE CIRCULAR.

13 Anticipated savings compared with our previous generation filling machines.

14 First launched as SIGNATURE EVO.

15 Association of Plastic Recyclers (APR).

16 Based on independent ISO-compliant life-cycle assessments.

17 Or in some cases REDcert2.

18 Excluding negligible constituents, such as inks and pigments.

19 Via an independently certified mass balance system.

20 Based on cradle-to-customer gate carbon footprint calculation.