Resource+

We are accelerating progress towards a circular economy that eliminates waste and regenerates nature

At least

85

%

paper content in aseptic carton targeted by 2025

At least

90

%

paper content in aseptic carton targeted by 2030

Recycle-ready

bag-in-box and spouted pouch solutions available for all our relevant market segments targeted by 2025

Packaging prevents the occurrence of food loss and waste during filling, distribution, storage and consumption. At the same time, various negative impacts on the environment arise along our value chain due to the waste generated and potential land and water pollution caused by mismanaged waste disposal.

Through sustainable raw material sourcing, we help to ensure the availability of necessary resources for the future. Our cartons are made mainly from renewable paper content and are designed for recycling. We offer innovative solutions that enhance circularity by eliminating aluminum foil, linking polymers to renewable or recycled materials, tethering caps, and replacing plastic with paper straws. Potential and actual impacts from raw material sourcing including air and water pollution primarily relate to the sourcing practices of suppliers and not to our own operations and we address these through our responsibility requirements for suppliers. See Our Supply Chain.

We are also innovating to make more of our bag-in-box and spouted pouches recycle-ready1 and to link their polymer content to post-consumer recycled plastics.2

We strive to optimize material use by lightweighting our packaging (including closures and connection systems), minimizing production waste, and by making our filling machines even more efficient. Lightweighting and minimizing waste also reduce related air and water pollution from raw material production. Certified systems help us to continuously improve resource use – including managing waste and water – in our operations and supply chain.

Our Resource+ commitments are in line with the Ellen MacArthur Foundation circularity principles and help customers reduce the environmental impact of their packaging, comply with growing regulations that mandate Extended Producer Responsibility (EPR) for packaging waste, and reduce resource use for filling lines at their factories.

Our Resource+ ambitions

1Achieve a 90% collection and 70% recycling rate for our beverage cartons in Europe by 2030

2Offer a recycle-ready1 bag-in-box and spouted pouch solution in all our relevant market segments by 2025

3Keep materials in circulation by offering renewable and/or recycled polymer content2 for all our packaging by 2025

4Help eliminate litter by increasing used packaging collection worldwide through our advocacy efforts

5Partner with industry and stakeholders to strive for recycling at scale for all our packaging in all our priority markets

Our commitments

We strive to lead the way towards a fully circular packaging system and we are committed to supporting the transition to a circular and responsible economy through the integrated management of the environmental and social impacts of our products. Our ambitious targets aim to increase renewable and recycled content, offer more recycle-ready bag-in-box and spouted pouch solutions, using only renewable energy, and foster collection and recycling of used packaging at scale.

We are committed to the principles of the circular economy, set out by the Ellen MacArthur Foundation, to design out waste, regenerate our natural systems, and keep products and materials in circulation – all underpinned by the use of renewable energy.

In Europe, we are fully committed to the 2030 roadmap of ten industry commitments (see below) set out by the Alliance for Beverage Cartons and the Environment (ACE), of which SIG is a member.

We are committed to monitoring and managing environmental impacts from our operations – including minimizing waste and use of resources. We are also committed to minimizing waste and related impacts at the supplier and downstream level. We minimize emissions to air, land and water from our operations applying the BAT principle (Best Available Technology).

We are committed to keeping hazardous waste at a minimum by adhering to legal regulations and to eliminating hazardous waste that is non-recyclable or non-reusable. To address the potential risk of land and water pollution from packaging waste being littered, we engage in a wide range of collection and recycling initiatives – see below.

We are committed to conservative water use throughout the product supply chain and business operations and strive to responsibly use water resources by considering water quantity, quality aspects such as water pollution and water stress risks. Our engagement to address water scarcity and stress in certain regions focuses on reducing the water use and consumption of our filling machines. Additionally, we aim to pass on our commitment to our customers by supporting them in improving their water efficiency and water stewardship.

ACE 2030 roadmap: industry commitments in Europe

Through ACE, together with others in our industry, by 2030 we are committed in Europe to:

- Produce beverage cartons only from renewable materials

- And/or produce beverage cartons from recycled materials

- Use more fiber1 and less plastic

- Decarbonize our value chain in line with 1.5°C target

- Deliver the lowest carbon footprint packaging

- Design for circularity

- Achieve a 90% collection rate of beverage cartons for recycling

- Achieve at least a 70% recycling rate verified by third parties

- Meet the highest sustainability sourcing standards for all materials

- Increase carbon sequestration, enhance biodiversity, and increase forest growth

Our approach

Measures to achieve Resource+ ambitions

- To accelerate progress toward meeting EU collection and recycling targets, we are working closely with pan-European and national associations to enhance EPR implementation. This includes improving existing EPR schemes to secure adequate funding for the collection, sorting, and recycling of beverage cartons across Europe.

- We conduct annual reviews of country-specific roadmaps for all priority markets, which account for approximately 90% of SIG’s business. Each roadmap outlines an advocacy strategy to support regulatory developments, steps to boost collection and recycling rates, and SIG flagship projects aimed at raising awareness and demonstrating best practices.

- We are expanding product development to offer recycle-ready alternatives in our spouted pouch and bag-in-box portfolios across all our segments.

- We are increasing our involvement in industry associations and producer responsibility organizations to actively support regulatory advancements in all priority countries.

Key pillars of our circular packaging strategy

- Paperization and increased use of recycled content

- Use of production residues and industry waste

- Design for recycling

- Advocating circular packaging

- Increase collection and recycling

- Optimize resource use in filling and pack production

- Responsible resource management

Paperization and increased use of recycled content

SIG is actively increasing the paper content in its beverage cartons to enhance renewability, further reduce the carbon footprint, and simplify recycling. With an interim target of 85% paper content, SIG aims to improve pulp yield at paper mills and ensure compatibility with standard paper recycling facilities. This approach is particularly crucial in markets without dedicated beverage carton recycling infrastructure, helping to unlock recycling opportunities in emerging regions.

We aim to lead the industry for renewable content by continually increasing paper content in our flagship aseptic cartons,3 and to comply with regulatory requirements on post-consumer recycled plastic content in every relevant SIG packaging. We are building on a strong base:

- All our cartons are made of around 75% of renewable forest-based paperboard.

- The paperboard makes use of wood chips and saw dust residues from sawmills. Shares vary by paper mill and in 2023 were up to 36%.

- We offer forest-based polymer solutions2 for all our aseptic cartons.

- Forest-based polymers are linked to tall oil as a feedstock. Tall oil is a wood component and residue in papermaking.

- About 95% of the procured aluminum foil in 2024 links to industry waste input.

- We offer the world’s first full barrier aseptic carton packaging material with paperboard and polymers linked to forest-based renewable materials4 and no aluminum layer.

- We offer circular polymer solutions linked to post-consumer recycled plastics2 for all our aseptic cartons.

We are now targeting increased paper content in our full barrier aseptic cartons. In addition, we are looking for ways to reuse valuable resources by linking our packaging materials to recycled content. We already offer SIG Terra Circular polymers linked to post-consumer recycled plastics2 for aseptic cartons and we are piloting circular polymers for bag-in-box. These solutions can also support customers in meeting forthcoming regulations mandating the use of recycled content in plastic packaging. We use a mass balance system, independently verified through ISCC PLUS certification,5 to link polymers in our packaging materials to renewable or recycled materials.

The mass balance system supports a transition away from virgin fossil-based materials within the conventional and highly efficient polymer industry. It is endorsed by the Ellen MacArthur Foundation as a valid way to support the circular economy.6

Design for recycling

Recyclability plays a key role in conserving resources and protecting the environment. If not correctly disposed of at the end-consumer stage, product waste can have negative impacts on the environment, including land and water pollution. If properly handled, however, used products can have a positive impact through recycling and energy recovery.

All our cartons are already designed for recycling and we are innovating to make more of our bag-in-box and spouted pouch solutions recycle-ready. To help us design packs that are not only technically recyclable but are also widely accepted in available recycling streams, we follow industry guidelines. These include design for recycling guidelines for cartons that we helped to establish through ACE and 4evergreen, as well as guidelines from CEFLEX, Recyclass and the U.S. Association of Plastic Recyclers (APR) that apply to our bag-in-box and spouted pouches. We have also introduced internal sustainable packaging guidelines, including detailed criteria on design for recycling, for our polymer bag-in-box and spouted pouch solutions.

Simplifying the design of packaging by reducing the number of different materials that go into a pack can enable recycling more widely. Our industry-leading aseptic carton solutions with no aluminum layer offer the potential to simplify the recycling process – with just two materials to separate rather than three. This can also enhance the quality of the recycled polymers recovered. Increasing paper content in our aseptic cartons will enable the packs to be recycled in regions where only paper recycling streams are available.

The SIG Terra portfolio already includes recycle-ready bag-in-box and spouted pouch solutions, and we are innovating to expand the recycle-ready range with a strong focus on solutions that are made mostly from a single type of polymer to facilitate recycling. The cardboard boxes – not manufactured or sold by SIG – that make up the majority of the materials in bag-in-box solutions can already be recycled through widely available paper recycling streams.

Advocating circular packaging

Driving progress towards a circular economy is not something we can do alone. We collaborate with industry partners, customers, governments, non-governmental organizations and communities to develop and implement solutions.

Through industry partnerships, we drive initiatives to create common industry guidelines, develop and share best practices, support enabling legislation, build recycling capacity, improve collection systems, and raise consumer awareness.

Advocating through industry associations creates a stronger voice for favorable recycling policies and regulations at global, regional and national level.

EPR is one of the enabling regulatory frameworks we advocate. EPR legislation incentivizes uptake of recyclable packaging and investment in collection, sorting and recycling infrastructure by holding manufacturers responsible for their products and packaging through the life cycle. In cases where EPR legislation alone does not achieve high collection rates, we support the use of deposit return schemes to encourage people to return used items for recycling.

We also work with partners to develop effective systems for collection and recycling in countries where there is no enabling legislation.

Industry partnerships

We collaborate through industry partnerships at global and regional levels:7

We are also part of national producer responsibility organizations (PROs), industry associations, and other interest groups that seek to promote recycling in countries such as Australia, China, India, Indonesia, Malaysia, New Zealand, South Korea, Thailand, the USA and Vietnam.

Fostering collection and awareness

Used packaging must be collected before it can be recycled. We support the development of effective collection systems and encourage consumers to recycle packaging materials instead of discarding them as litter or sending them to landfill, which can have a negative impact on the environment, including land and water pollution.

Our tailored Going Circular roadmaps are designed to catalyze collection and recycling in our priority countries that together account for around 90% of our global packaging sales (by weight). Many of the programs we support have a wider positive impact by increasing collection and recycling of other types of packaging as well as ours.

Local programs use innovative models for waste collection that provide additional social benefits. These include ethical labor conditions for waste workers through our municipal recycling model in Brazil, the use of blockchain technology in Egypt, and rewards offered in exchange for waste collected in underprivileged communities in Brazil and Indonesia.

We also partner with customers to raise awareness of sustainable packaging and the importance of recycling through on-pack labeling and communications campaigns.

Increasing recycling capacity

We are supporting the development of infrastructure to enable our packs to be recycled at scale, with an initial focus on recycling of used beverage cartons.

The high-quality fiber in paperboard can be separated and recycled relatively easily for reuse at paper mills. We are therefore focusing on increasing capacity to recycle polymer and aluminum – either together as a robust PolyAl material for roof tiles or furniture, or separately to enable wider applications for the recycled materials. Infrastructure is already in place for recycling PolyAl, including at facilities in which we have invested located in Australia, Germany, and Brazil. Through EXTR:ACT, we monitor development of new recycling technologies and facilities being developed independently and through industry associations.

We aim to incentivize development of recycling infrastructure by creating a market for recycled materials – including innovating to use recycled content for our packs.

Optimizing resource use in filling

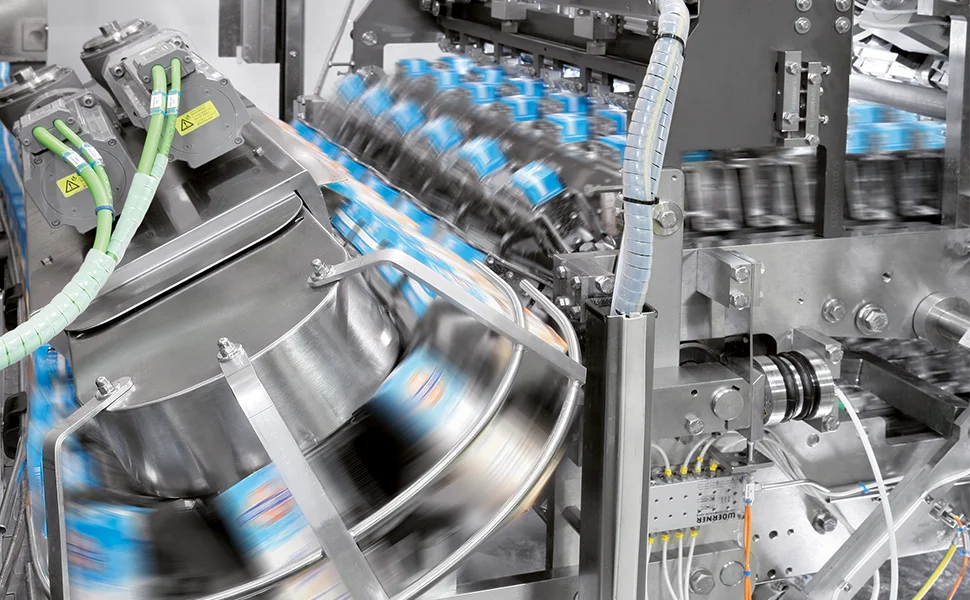

Our aseptic carton filling machines have an industry-leading low waste rate that means less than 0.5% of our packs are wasted during the filling process (see Sustainable innovation).

Through our SIG EcoFill Consulting program, we support aseptic carton customers in identifying ways to reduce resource use in the filling lines at their factories. We also aim to improve the efficiency of our filling machines for chilled cartons, and plan to review opportunities to reduce resource use in filling our bag-in-box and spouted pouch solutions.

We work with customers to ensure that our filling machines, and their parts, are recycled or disposed of responsibly at end-of-life.

For our aseptic carton filling machines, we provide guidance on target water use to ensure efficient operation at the customer stage and we offer water reduction kits.

Optimizing resource use in filling in 2024

22 customers reduced resource use with the SIG EcoFill Consulting program. In 2024, we helped them achieve annual savings of around 41 million liters of water, 570,240 m3 of compressed air, 108 MWh of energy, and approx. 38 metric tons of CO2 emissions.

33 water reduction kits sold, designed to cut water consumption by up to 50%

Semi-automated cleaning machines cut water use by 54% compared with manual cleaning

Continued placement of our next-generation filling machine SIG NEO, designed to reduce overall use of utilities by 30% on average

Managing resources responsibly in our supply chain

We strive to ensure responsible management of natural resources in the supply chain by sourcing our raw materials with certifications to rigorous external standards, such as FSC™ for paperboard and ASI for aluminum foil (see Our supply chain).

Both these certifications include requirements to conserve natural resources. In addition, relevant sustainability topics are covered through our working groups with paperboard suppliers and we are engaging with aluminum suppliers to increase content from post-industrial waste in the foil we purchase.

Our self-assessment of A-material suppliers using the WWF Water Risk Filter found that none has a substantive impact on water, but our paperboard suppliers are dependent on access to water for the papermaking process.

Circularity Strategy – Brazil: A Holistic Approach to Recycling

Brazil faces a major recycling challenge with 82 million tons of waste generated annually, of which only 4% is recycled. This issue is not just environmental but also social, affecting around 1 million waste pickers, 90% of whom work informally and earn less than the minimum wage.

To address these challenges, a systemic approach is needed that considers every link in the chain:

- Citizen Engagement: Through the so+ma program, we are incentivizing citizens to recycle by offering rewards for responsible behavior. Currently, there are six so+ma houses operating in Curitiba and Campo Largo, with plans to expand. In 2024, we will pilot new initiatives including door-to-door selective collection rewards, an entrepreneurship program for women in recycling, and a gamified recycling education campaign for schools. In 2024 there was an entrepreneurship program for women in the recycling sector and new initiatives are to come, such as a program to encourage citizens to take part in door-to-door selective collection and a gamified recycling education campaign for schools.

- Infrastructure & Public Policy: The Recicleiros program supports municipalities in implementing selective collection and structuring cooperatives. Today, we are active in 14 municipalities. Special projects include free training for public managers, an academy for waste pickers in partnership with major companies and Brazil’s Ministry of Environment, and the Vox Lab platform, which aims to promote behavioral change towards recycling. Additionally, we are testing SIG’s digital traceability technology to ensure transparency and accountability in the supply chain.

- Recycling Technology: Our new recycling plant, set to open in 2025, will improve the recycling process by separating the aluminum and polyethylene layers of carton packs. This technology will boost the value of recycled materials and increase the recycling rate by offering better financial incentives to cooperatives.

- Ethical Circular Supply Chain: To ensure responsible sourcing, we are working with Earthworm Foundation and the government of Paraná to create an ethical supply chain platform. This initiative will assess cooperatives, develop protocols for good practices, and offer better remuneration for cooperatives that meet these standards. Our goal is to build a responsible and traceable supply chain that benefits both the environment and the people working in it. Since its launch in 2018, our initiatives have collected nearly 20,000 tons of waste. In 2024 alone, we engaged 3,888 families through the So+ma Vantagens program at 7 collection points. Additionally, the Recicleiros Cidades program reached approximately 1 million people across 14 municipalities, facilitating the collection of around 7,240 tons of recyclable materials and creating 302 jobs.

This circularity strategy goes beyond environmental goals by addressing social issues, ensuring that recycling in Brazil is not only efficient but also fair and responsible. Through partnerships with NGOs, government bodies, start-ups, and communities, we are building a sustainable and ethical recycling chain.

SIG and partners launch recycling and livelihood project in Egypt

SIG, in partnership with Plastic Bank and Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH, has launched a project to transform Egypt’s recycling efforts while improving the livelihoods of waste collectors through blockchain technology. Egypt generates around 100 million tons of waste annually, of which 40 to 85 per cent is collected in urban areas and only 0–35 per cent in rural areas. This new three-year initiative aims to collect 700 metric tons of beverage cartons and enhance the lives of more than 1,000 local waste collectors. Using the PlasticBank® app, powered by blockchain, waste collectors can track their work, earn digital rewards, and access social benefits like health insurance, grocery vouchers, and school supplies.

In 2024, the GIZ Developp project, Green Jobs from a Box, successfully collected an additional 63 tons of beverage cartons. The initiative currently engages 70 waste workers who are involved in the collection and sorting of various packaging materials, including beverage cartons. Notably, this marks the first time that Plastic Bank has integrated beverage cartons into its collection efforts in Egypt. The system ensures full traceability, providing transparency on the quantity of cartons collected and the individuals involved in the process. The fibers from the cartons are repurposed into locally produced paper, while the reject material—referred to as PolaAl (polymer-aluminum fraction)—is utilized as a substitute for raw materials in the production of interlock bricks by the local partner, TileGreen. This creates a fully integrated recycling cycle in Egypt, supporting both environmental sustainability and local economic growth.

The project not only addresses immediate recycling needs but also supports the development of an Extended Producer Responsibility (EPR) model in Egypt. It aligns with the Egypt Waste Management Regulatory Authority to integrate recycling into the national framework.

Through this collaboration, we have unlocked the true potential of beverage cartons as a resource, ensuring they remain in circulation. For the packaging, beverage, and food industries, this system repurposing beverage carton components into locally demanded materials represents a way to minimize waste disposal costs and maximize resource efficiency. It provides a replicable model that can inspire sustainable practices worldwide, advancing circular economy principles and setting a precedent for innovation in waste management.

Establishing Egypt’s first complete recycling process for beverage carton

Continuous improvement in our operations

We are committed to monitoring and managing environmental impacts from our operations. Robust environmental management systems, certified to ISO 14001 at all our production plants, support continuous improvement across our operations.

Minimizing use of water

We use relatively little water in our operations, and water is not identified as a material topic in our double materiality assessment for our own operations. However, we strive to use water resources responsibly by considering water quantity, quality and water stress risk, and aim to minimize consumption where feasible. All plants install flow meters to track specific water use to identify plant areas with high consumption.

We track monthly water consumption and water withdrawal data at all plants, including withdrawal of fresh surface water (lakes, rivers, etc.), fresh groundwater, and water discharge (water returned to the source of extraction at similar or higher quality as raw water extracted).

Sites in water-stressed areas, identified through a self-assessment using the WWF Water Risk Filter, are required to have water management systems.

Water storage only takes place in fire water tanks. This would only have a significant impact if the tanks needed to be refilled.

We have a minimum quality standard for effluent discharge: chemical oxygen demand (COD) is measured against legal limits at all our locations.

A total 557,148m3 of water was supplied to SIG Group in 2024, including 314,659m3 in water-stressed areas8. We discharged 331,008m3 of waste water in 2024 (around 41% of the total supply), including 127,974m3 in water stressed regions (plants in water-stressed areas – Merced/USA, Queretaro/Mexico, Riyadh/Saudi Arabia and Suzhou/China.

Minimizing waste

Our main focus is on eliminating waste from operations to landfill by reusing or recycling waste – or, where this is not feasible, by choosing the next best option, such as energy recovery. We also implement responsible disposal options for hazardous and electronic waste to avoid environmental harm and ensure hazardous waste does not end up in landfill.

Assessing effectiveness

Water use in production

- Monthly reviews of the global performance (water-related KPIs).

- Plant specific water usage is measured and reported on a monthly basis.

- Water risks are assessed regularly for the next 1 to 3 years in an environmental risk assessment.

- Business impact evaluation of possible shortages or allocation of water supply to production capacity of plants.

- Annual evaluation and plant classification in water stress areas by the central CR team.

- ISO 14001 impact assessment.

Production waste

- Robust life-cycle assessments (LCAs) carried out by independent experts using the ISO 14040 international standard and critically reviewed by an independent panel.

- Monthly reporting of waste and circularity-related KPIs.

- Annual limited assurance by PwC on environment data.

- Filling machines are predominantly refurbished and most of the material can be recycled at end-of-life.

Food waste

- Our packs prevent food loss and waste during filling, distribution, storage and consumption

Minimizing waste and water use in our value chain

Water use and waste are included in our engagement with the value chain. Relevant aspects are covered by management approaches which we follow to further reduce the environmental footprint of our products and our activities related to responsible sourcing and circularity. Waste relates to resource efficiency in our supply chain but also to production waste which occurs in using our filling machines and to the contribution of used packaging to industrial and household waste streams. Water use occurs to a relevant extent in all main commodity supply chains and also when operating our filling machines. Like pollution of air also pollution of water mainly occurs along the major commodity supply chains.

Below are some examples how waste and water and pollution of water and air in our upstream supply chain are addressed in our sustainability approach:

- At the supplier level, our responsible sourcing approach with ASI certification of the aluminium foils supply chain includes strong provisions for treatment of industrial wastes along the production chain from bauxite mining, alumina refinery and smelting operations. Water use and waste water treatment and industrial pollution are also addressed within the ASI performance standard which is tailored to material impacts of the different operations in the supply chain. See Sourcing responsibly

- Designing our filling machines towards less utility demand and increased efficiency helps to reduce both consumptive water use and the creation of non-product output. See Sustainable innovation

- Our technical service teams help aseptic carton customers minimize the use of water, energy and compressed air in their factories, through upgrade kits for existing machines and the SIG EcoFill Consulting program. See Resource+

- For the management of post-consumer waste, we have established country specific roadmaps for all priority markets cover approx. 90% of SIG business, on increasing circularity which includes action to increase collection of used packaging for recycling and by ensuring recyclability for all packaging materials delivered. See Resource+

- Product design and innovation is accompanied by Product Life Cycle Assessments following ISO 14040. All relevant environmental impacts are covered including impacts of emissions to water and air. This allows to detect hotspot along the value chain and interact by e.g. raw material substitution. In many cases greenhouse gas emissions are correlated e.g. with the emission of sulfur dioxide or particulate matter which are other main pollutants where fossil fuels are burnt – so also our climate + strategy helps to reduce pollutants e.g. by shifting to less energy intensive raw material supply chains. See Climate+

Grievance mechanisms are set up as part of local collection and recycling partnerships or grievances can be reported through the Integrity & Compliance Hotline.

Responsibility for managing raw material sourcing, waste and circular economy

- Global Sourcing & Procurement The Responsibility Steering Group oversees semi-annual reports on raw material sourcing

- Monitoring and reducing water use in our operations: global and local Environment, Health & Safety teams

- Design for recycling and recycled content: Global Technology and Global Marketing

- Regional sustainability manager together with the local teams are responsible for helping to drive progress on collection and recycling, with oversight from Regional Presidents

Minimizing waste in production

We are committed to minimizing waste at the supplier and own production levels and downstream. Waste in own operations is not identified as a material topic in our double materiality assessment.

Production waste by disposal method in 2024

Production waste rate for aseptic carton

(grams of waste per m2 of sleeves produced)

Production waste by type (thousand metric tons)

|

|

20201 |

|

20211 |

|

20221 |

|

2023 |

|

2024 |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Raw and laminated carton |

|

48.4 |

|

58.3 |

|

57.3 |

|

62.5 |

|

71.1 |

||||

Polyethylene |

|

1.6 |

|

3.5 |

|

3.3 |

|

9.3 |

|

10.1 |

||||

Hazardous waste |

|

2.9 |

|

3.7 |

|

3.8 |

|

6.5 |

|

10.9 |

||||

Aluminum (<1%) |

|

– |

|

– |

|

0.3 |

|

0.3 |

|

0.4 |

||||

Total |

|

53.1 |

|

65.5 |

|

64.7 |

|

78.6 |

|

92.5 |

||||

|

||||||||||||||

Production waste by disposal method (metric tons) in 2024

|

|

Non-hazardous |

|

Hazardous |

|

Total |

||||

|---|---|---|---|---|---|---|---|---|---|---|

Recycled |

|

78,106 |

|

269 |

|

78,375 |

||||

Reused |

|

2,192 |

|

483 |

|

2,675 |

||||

Recovered from energy |

|

1,006 |

|

652 |

|

1,658 |

||||

Landfill |

|

1,252 |

|

205 |

|

1,457 |

||||

Other disposal options1 |

|

500 |

|

102 |

|

602 |

||||

Total |

|

83,055 |

|

1,712 |

|

84,767 |

||||

|

||||||||||

Our targets and performance

Targets, progress and performance

Target |

|

Progress tracker |

|

2024 performance |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Material topic: Waste and circular economy |

||||||||||||||

Launch a full barrier carton with all main materials linked to renewable |

|

|

SIG Terra Alu-free + Full barrier had its first commercial launch in 2023 in China and sales continued to scale up during 2024. This is the world’s first full barrier solution for aseptic carton packs with no aluminum layer that can be used with oxygen-sensitive products, such as juices, as well as liquid dairy. In 2024 we added the Forest-based polymers as an option to create SIG Terra Alu-free + Full barrier + Forest-based polymers, thereby achieving the target one year early. |

|||||||||||

Develop a full barrier aseptic carton with at least 85% paper content (excluding closure) by 2025 – and at least 90% paper content (including closure) by 2030 |

|

|

During 2024, we successfully finalized a technical pre-study for increased paper content, which will enable our cartons to be recycled in regions where only paper recycling streams are available. We completed an internal global compatibility study of this future packaging structure with paper mills to further guide the new structure development. |

|||||||||||

Offer a recycle-ready2 bag-in-box and spouted pouch solution in all our relevant market segments by 2025 |

|

|

We have expanded our offering of recycle-ready spouted pouches as well as recycle-ready bag-in-box solutions: our SIG Terra RecShield D bag-in-box package for post-mix syrup, our largest segment, has been formally recognized by the Association of Plastic Recyclers (APR) for meeting the highest criteria for recyclability according to the APR Design® Guide for Plastics Recyclability. |

|||||||||||

Partner with stakeholders to implement dedicated and country-specific roadmaps to support increased collection and recycling of beverage cartons, bag-in-box, and spouted pouches in priority countries that account for more than 90% of our global packaging sales (by weight) by 2025 |

|

|

We have Going Circular local roadmaps in priority countries that together account for 90% of our global packaging sales (by weight) – including priority countries identified this year for our bag-in-box and spouted pouch businesses. We continued to partner with industry, governments, municipalities, customers, and communities to implement local programs to support increased collection and recycling. These include: a new partnership with the German Development Cooperation in Egypt that monitors ethical working conditions for waste collectors; the expansion of our social model for collection to Indonesia; new recycling facilities in development in Australia and Brazil; and awareness and collection programs in a range of other countries. In Europe, our focus is on developing common industry guidelines and advocating effective policies to enable more collection and recycling of used packaging. |

|||||||||||

Scale up and expand our community recycling model by 2025 |

|

|

The Recycle for Good initiative, launched in Indonesia in 2023 by the SIG Foundation, incentivizes recycling with a strong focus on used beverage cartons and polymer pouches. The program was expanded in 2024 to multiple pick-up points and households to reach more people and increase the collection rate of recyclable waste. |

|||||||||||

25% reduction in grams of waste per m2 of packaging material used to produce our aseptic cartons by 2025 (from 2016)4 |

|

|

Our waste rate from production of our aseptic carton packs has increased by 6.5% in 2024 and decreased by 5.7% from 2016. Main reason for the waste rate increase is the ramp-up phase of various new production equipment. |

|||||||||||

Zero landfill – all waste to be recycled or used as renewable biofuel by 2025 |

|

|

95.7% of waste from production was reused or recycled, 1.7% was recovered for energy, and around 1.6% went to landfill. We have achieved zero waste to landfill at 20 of our production plants. |

|||||||||||

Maintain certification to ISO 14001:2015 at all production plants |

|

|

We maintained our global ISO 14001 certification in all plants. |

|||||||||||

|

||||||||||||||

Progress in 2024

We continued to invest in and support development of new recycling facilities for used beverage cartons

- In Brazil, we continued the construction of a new recycling plant for beverage cartons that will use innovative technology to separate the polyethylene from the aluminum in PolyAl to create a wider market for these recycled materials, with the expectation of increasing their value by more than 50%. The recycling plant is part of SIG’s ethical recycling strategy in Brazil in collaboration with our local paper mill recycling partner Revita – see feature.

- 2024 saw the ramping up of Saperatec, a second PolyAl recycling facility in Germany in addition to Palurec, in which we co-invested with industry partners. Existing facilities can already process around 30% of the total PolyAl produced from recycled beverage cartons in Europe, and a significant increase in capacities is planned in the near future to increase this to 40%.

Fostering collection and awareness

As well as supporting recycling infrastructure, we have continued to establish local partnerships to raise awareness and improve collection rates as part of our Going Circular roadmaps in priority countries. We carefully select our collection and recycling partners and aim to avoid any negative impacts by closely monitoring our partners’ human rights policies. In addition, we are exploring the implementation of a streamlined process to enhance our assessment efficiency.

KPIs

Metric |

|

2020 |

|

2021 |

|

2022 |

|

2023 |

|

2024 |

||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Resource+ |

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

Material topic: Waste management & circular economy |

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

SIG carton packaging that is designed for recycling1 (%) |

|

1007 |

|

1007 |

|

1007 |

|

100 |

|

100 |

||||||||||||||||

SIG bag-in-box and spouted pouch packaging that is recycle-ready2 or for which we offer alternative recycle-ready bag-in-box and spouted pouch solutions (%) |

|

– |

|

– |

|

– |

|

69 |

|

76 |

||||||||||||||||

SIG packaging portfolio that is recycle-ready3 (%) |

|

– |

|

– |

|

– |

|

90 |

|

91 |

||||||||||||||||

Waste rate for aseptic carton production (grams of waste per m2 of packaging material)5 |

|

32 |

|

34 |

|

32 |

|

31 |

|

33 |

||||||||||||||||

Waste rate for carton production4 (grams of waste per m2 of packaging material)5 |

|

– |

|

– |

|

– |

|

– |

|

35 |

||||||||||||||||

Waste rate for production (bag-in-box and spouted pouch) (tons of waste per thousand tons produced)6 |

|

|

|

|

|

|

|

1.9 |

|

3.0 |

||||||||||||||||

|

||||||||||||||||||||||||||

Our positive impact

Through our Resource+ actions, we contribute to the United Nations Sustainable Development Goals.

2024 success stories

Launching the Food and Beverage Carton Alliance

Together with industry partners Tetra Pak and Elopak, and key suppliers Stora Enso and Billerud, SIG announced the formation of the Food and Beverage Carton Alliance. This global association builds upon the strong foundation of the European Alliance for Beverage Cartons and the Environment (ACE) and integrates the expertise of EXTR:ACT, its technical arm. This new alliance will expand our efforts on a global scale.

The alliance is structured around three core components:

- Advocacy: to engage policymakers worldwide to help solve global policy challenges and advocate for public policies that recognize the essential role of food and beverage packaging, support green innovation, and encourage the transition to low-carbon, circular economies.

- Communication: to ensure that information about our solutions – whether related to climate mitigation, circular economies, or food system resilience – is accessible to all. Our goal is to increase awareness of the benefits we bring.

- Center of Expertise: technical solutions, innovations and industry data globally and locally, will provide evidence-based insights. Consolidated research and non-competitive industry data will set benchmarks for progress and action across the sector.

Accelerating Circularity: SIG partners with Ellen MacArthur Foundation

SIG has strengthened its commitment to sustainability by partnering with the Ellen MacArthur Foundation, a global leader in circular economy initiatives. This collaboration aims to accelerate the transition to fully circular packaging solutions worldwide. By leveraging the Foundation’s expertise and network, SIG will focus on reducing waste, improving recyclability and promoting the use of renewable materials. The partnership is a key step in SIG’s broader strategy to innovate and scale sustainable packaging practices, driving meaningful progress toward a waste-free, low-carbon future for the packaging industry.

First industry aligned assessment protocol for fiber-based composite packaging

In 2024 EXTR:ACT received the final assessment protocol for the recyclability evaluation of fiber-based composite packaging to be recycled in specialized paper mills dedicated to used beverage cartons. This recycling assessment methodology created for EXTR:ACT in cooperation with Certify is aligned with many other EU methodologies for packaging materials.

1 In line with Design for Recycling criteria developed by APR (Association of Plastic Recyclers) and Recyclass.

2 Via an independently certified mass balance system.

3 Top five SIG aseptic carton formats by sales volume.

4 Excluding negligible constituents, such as inks and pigments. Polymers linked to wood residues from papermaking via an independently certified mass balance system.

5 Or in some cases REDcert2.

6 The Ellen MacArthur Foundation Mass Balance White Paper.

7 In January 2025 the Food and Beverage Carton Alliance was formed through the merger of ACE and EXTR:ACT with the aspiration of acting not only in Europe but also globally.

8 Based on an assessment using the WWF Water Risk Filter.